Friday, 22 November 2024

DIY Pallet Shed: How to Build a Shed Using Reclaimed Pallets

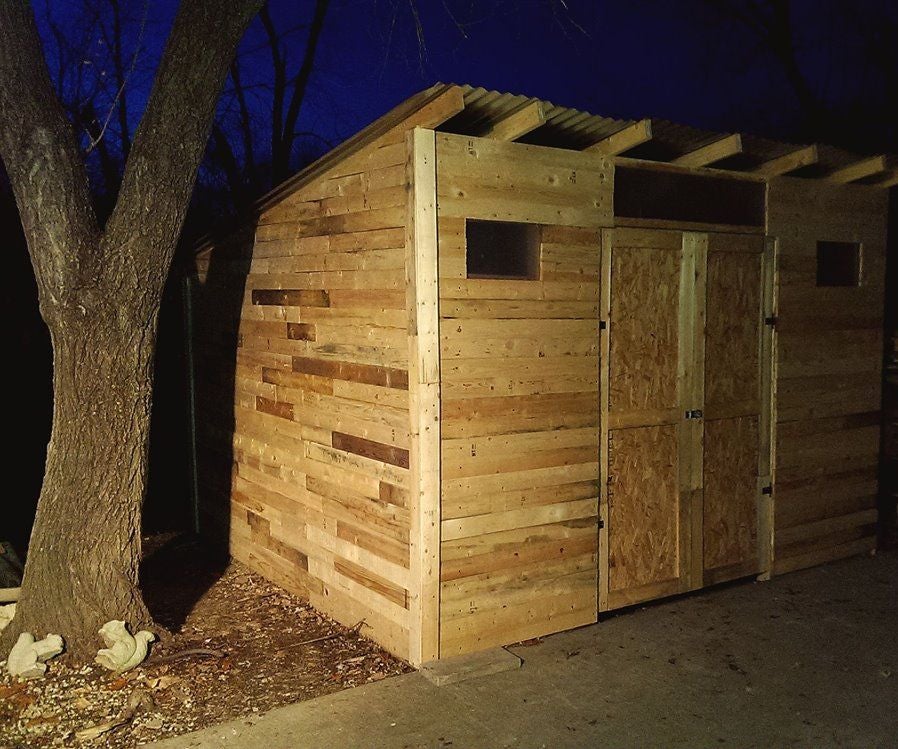

DIY Pallet Shed: A Comprehensive Guide to Constructing a Shed from Reclaimed Pallets

Constructing a shed from reclaimed pallets presents a cost-effective and environmentally conscious alternative to purchasing a pre-fabricated structure. This guide provides a detailed, step-by-step process for building a functional and aesthetically pleasing shed utilizing this readily available material. However, it is crucial to acknowledge that using reclaimed pallets introduces certain challenges and considerations that require careful planning and execution.

Phase 1: Planning and Preparation

Before embarking on the construction process, meticulous planning is paramount. This phase encompasses several key aspects that will significantly impact the final outcome and the overall success of the project.

Shed Design and Dimensions

The first step involves determining the desired dimensions of your pallet shed. Consider the intended use of the shed, the available space in your yard, and the number of pallets you have at your disposal. A detailed sketch or blueprint, even a simple one, will be invaluable throughout the construction process. Consider factors such as door placement, window placement (if desired), and roof pitch. Accurate measurements are critical to ensure proper fitting of the pallets and to avoid structural issues.

Pallet Assessment and Selection

Not all pallets are created equal. Inspect your reclaimed pallets carefully for damage, rot, infestation, and structural integrity. Discard any pallets showing signs of significant damage or decay. Prioritize pallets of consistent dimensions and quality for a more straightforward construction process. The condition of the pallets will directly influence the durability and longevity of your shed. Ensure the wood is relatively sound and free from splinters that could pose a safety hazard. The dimensions of the pallets are important; selecting pallets with consistent size simplifies construction greatly.

Materials Acquisition and Tool Preparation

Beyond the pallets themselves, you will require additional materials to complete the project. These include: concrete or other foundation materials, screws and nails, wood for framing or reinforcement (where needed), roofing material (e.g., asphalt shingles, corrugated metal), and any desired finishing materials (e.g., paint, sealant). Gather all necessary tools before commencing construction. This may include a hammer, screwdriver, drill, saw (circular saw or hand saw), measuring tape, level, safety glasses, work gloves, and potentially a post hole digger if you opt for a post and beam foundation.

Phase 2: Foundation Construction

A stable foundation is crucial for the longevity and structural integrity of your pallet shed. Several foundation options exist, each with its own advantages and disadvantages.

Concrete Slab Foundation

A concrete slab provides the most stable and durable foundation, offering excellent protection from moisture and pests. However, it requires more effort and expertise to pour and level. Ensure you obtain necessary permits before undertaking this method. A level and compacted base is crucial before pouring the concrete. Allow ample curing time for the concrete before proceeding with the shed construction.

Gravel Base Foundation

A gravel base offers a simpler and more affordable foundation option. It involves leveling the ground, laying down a layer of gravel, and compacting it thoroughly. While less stable than a concrete slab, a properly constructed gravel base can provide adequate support, especially on well-drained soil. This is suitable for lighter sheds and may not be sufficient in all soil conditions.

Post and Beam Foundation

A post and beam foundation consists of setting pressure-treated posts into the ground to support the shed's base. This method requires digging holes, setting the posts using concrete, and then constructing a framework using pressure-treated lumber on top. This can be a viable option in areas where ground conditions are less than ideal or where the ground is sloped.

Phase 3: Shed Construction

With the foundation completed, the process of assembling the shed using reclaimed pallets can begin. This stage requires patience, attention to detail, and the implementation of safe work practices.

Pallet Assembly and Wall Construction

Begin by assembling the pallet walls. Depending on the size and design of your shed, you may need to cut or modify some pallets to achieve the desired dimensions. Secure the pallets together using screws or nails, ensuring a strong and stable connection. Consider using additional wood framing to reinforce the structure and provide added stability. Use pressure-treated lumber for any ground-contacting components of the structure.

Floor Construction

The floor can be constructed using additional pallets or by building a framework from lumber and covering it with plywood or other suitable flooring material. Ensure the floor is level and securely fastened to the foundation or frame. Consider adding a vapor barrier beneath the flooring to protect against moisture.

Roof Construction

The roof design depends on your chosen shed design. It could be a simple gable roof, a shed roof, or other more complex design. Construct the roof frame using lumber and secure the roofing material. Ensure proper overhang to protect the walls from rain and weather. Use appropriate roofing materials suited for your climate and budget.

Door and Window Installation (If Applicable)

Install doors and windows (if desired) ensuring a snug fit and proper weatherproofing. Use high-quality hinges and locking mechanisms. For windows, consider using plexiglass or other weather-resistant materials. The door and window placement should have been pre-planned in the design phase.

Phase 4: Finishing Touches and Safety Considerations

Once the primary structure is complete, attention should be given to finishing touches and safety measures.

Weatherproofing and Sealing

Apply a suitable wood sealant or preservative to protect the pallets from moisture damage and extend the lifespan of your shed. Pay particular attention to joints and seams. Consider painting or staining the shed for additional protection and aesthetic appeal.

Safety Precautions

Throughout the entire construction process, prioritize safety. Wear appropriate safety gear including safety glasses, work gloves, and sturdy footwear. Use caution when handling tools and power equipment. Ensure proper ventilation if working with paints or solvents. Inspect the shed regularly for any potential hazards or signs of damage.

Building a shed from reclaimed pallets is a rewarding project that offers significant cost savings and environmental benefits. However, careful planning, meticulous execution, and a commitment to safety are essential for a successful outcome. This detailed guide provides a solid foundation for undertaking this project. Remember to adapt these instructions to your specific design and material availability.

No comments:

Post a Comment